A versatile maintenance management system you can commit to and rely on – now and in the future

VincitEAM is a continuously evolving system that always knows the state of your maintenance. It boasts incredibly versatile features, is easy to implement, and supports both workplace safety and business needs. With world-class document management and comprehensive information management, processes remain flexible, situational information is always accurate, and maintenance actions are proactive.

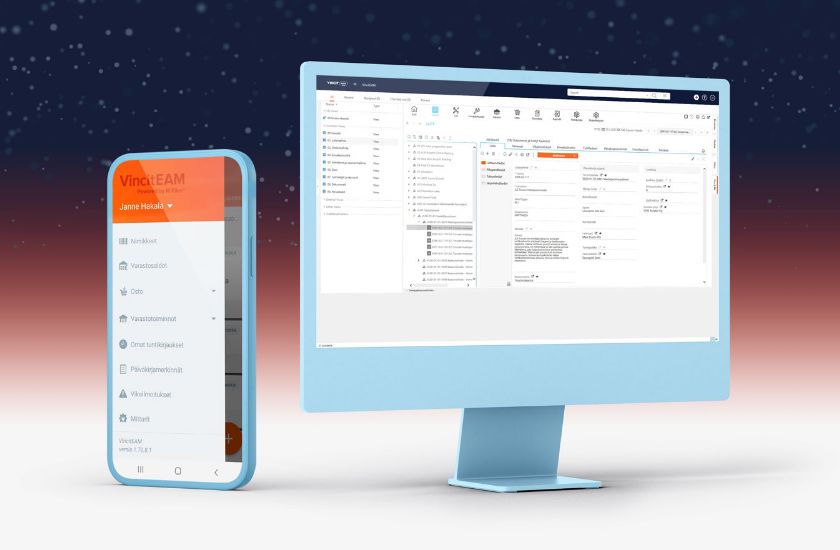

Ease of use

- A system that works seamlessly on both mobile and desktop.

- Speech recognition for reporting tasks is available.

- User interfaces tailored for all job roles are quick to adopt and easy to use – as reported by our clients.

World-class document management

- The only maintenance management system on the market with world-class document management capabilities.

- Seamless version control and a universal search engine that also utilises metadata.

- Facilitates flexible and versatile information management processes.

Efficient information management supports your operations

- Users have easy access to the information they need for their work, right where the work is performed.

- No more wasting time searching for the right information and documents.

- The system provides information such as equipment details, technical documents, work and safety instructions, spare parts, inventory details, and work orders.

Always up-to-date situational information

- Easily manage the big picture of your current maintenance status.

- All necessary information is relayed to the right people and is updated electronically and in real-time.

- Recording accurate information is easy and greatly improves precision.

Adaptation to the needs of your business

- The system is continuously developed in collaboration with users and configured to meet each customer’s needs.

- VincitEAM can be integrated into the user’s other information and control systems.

- We assist in transferring data from the user’s other systems and refining it for better usability.

Enhanced workplace safety

- Effortless and centralised management of competencies, qualifications, and work permits, including hot work and tank work permits.

- Collecting safety observations and processing them into corrective actions as needed.

- Risk assessments for locations and equipment, as well as job hazard assessments.

Maintenance planning with purpose

- Transition from calendar-based maintenance to usage-based or condition-based maintenance and predictive maintenance.

- Hybrid plans that allow for the use of multiple different approaches in a single maintenance plan.

- Improved equipment utilisation, more operating hours, fewer unnecessary maintenance tasks, and lower costs.